Bridging silos, generating insights, reimagining processes

Over the past several years, the Middle East’s adoption of improved drilling technologies, usage of data for operational excellence and leveraging IT OT integration has significantly benefited both efficiency and production, especially in the face of oil price turmoil. The potential benefits of going digital are clear: increased productivity, safer operations, and cost savings. In the energy production segment, challenges include adding sensors to decades-old wells and making sense of the stored production data. As analytics, AI and machine learning, computing power, and data science continue to converge, upstream companies can enable innovations to drive a competitive advantage.

One recent industry survey says that 70% of oil and gas leaders will invest more in digitisation over the next 3-5 years. Middle East oil and gas firms have an opportunity to hire and train their Millennial workforce with digital technology skills. Digital innovations can enhance supply chains, improve asset maintenance and safety.

While leveraging technologies such as Industrial Internet of Things and data analytics, SAP solutions provide the ability to build digital twins of physical assets, to predict equipment failure or pipeline corrosion, observe the related operational data geospatial, sensor, launch remediation, and manage a change process to eliminate the reoccurrence of the problem.

SAP Performance Benchmarking shows that more connected workers could lead to 15% more productivity by 2023. 87% of the oil and gas companies in the Forbes Global 2000 are SAP customers and they produce more than 78 million barrels of oil each day.

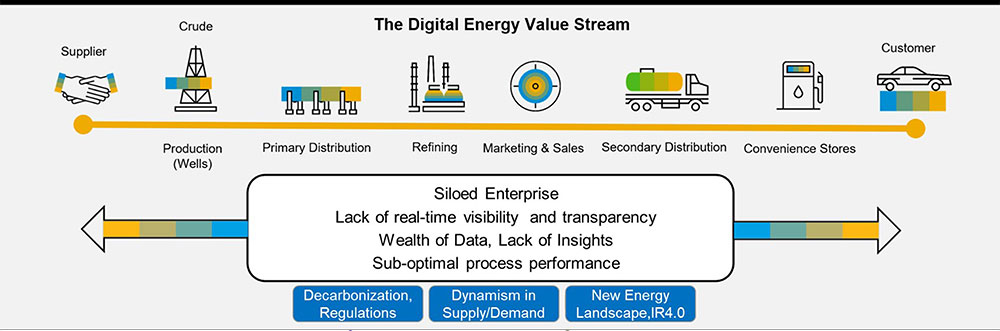

The energy landscape is changing given the needs of consumers and social organisations accentuated by government influences. There is a wave towards decarbonisation resulting in high growth for renewables while coal is increasing being substituted by gas.

This energy transition brings new dynamism to energy supply and demand. The industry faces slowing growth in emerging markets coupled with restrictions on trade and difficult geo-political environment especially in the Middle East.

Internally within organisations, energy companies need to bridge the silos and get real-time visibility and transparency across their enterprise. They need to leverage the wealth of data they have and develop capabilities to bring operational insights to empower decision makers. And they need to reimagine their processes and improve performance.

All these are putting pressure on margins and companies are having to redefine the way they look at their business and transform. Companies are increasingly relying on digital transformation leveraging Industrial Revolution 4.0 technologies to bring the next wave of efficiency gains and create new business models.

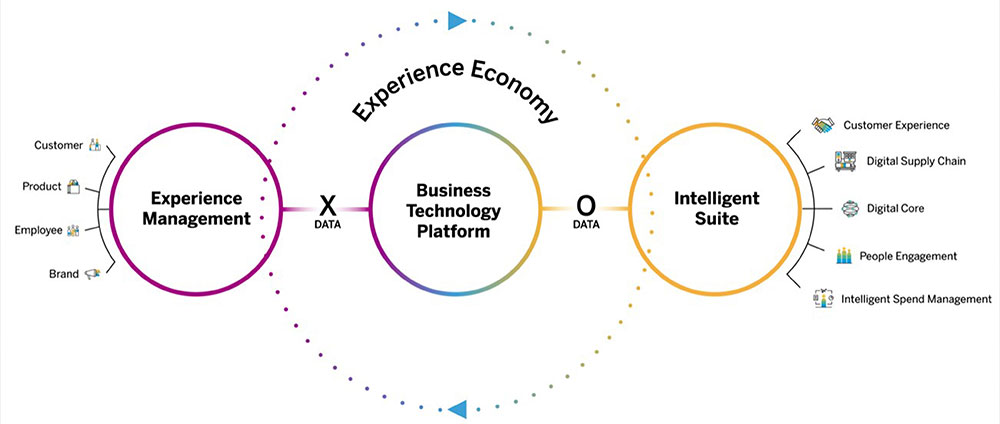

As the industry goes through IR 4.0 and digital transformation, they have three clear domains to focus on. They need to have a stable core operating platform that enables simplified day-to-day operations smartly, they need to have an innovation platform that enables them to pilot new reimagined processes and business models and they need to manage their end customer experience.

Key takeaways

- SAP Performance Benchmarking shows that more connected workers could lead to 15% more productivity by 2023.

- 87% of the oil and gas companies in the Forbes Global 2000 are SAP customers and they produce more than 78 million barrels of oil each day.

- One recent industry survey says that 70% of oil and gas leaders will invest more in digitisation over the next 3-5 years.